-

ColourSilvery, Black, Any Color Is Available As Per Require

-

Surface TreatmentAnodized, Powder Coating, Electrophoresis, Wooden-pattern Transfer...

-

LifetimeMore Than 10 Years

-

MOQ1Tons

-

Company HonorChina Famous Trademark

-

SkypeJames.wang0307

-

WeChatJameswang0307

-

WhatsApp/Viber/Mobile0086 18662963676

-

QQ1021035269

-

Production Capability6500 Tons/month

-

OEM/ODMAvailable

-

CO,FormA, FormB, FormE...Available

-

SamplesFree

-

Web1Http://www.profiles-aluminum.com

-

Web2Http://aluminum-extrusion.sell.everychina.com/

-

Place of OriginJiangyin, Jiangsu, China

-

Brand NameYueFeng

-

CertificationISO9001

-

Model NumberYF-150

-

Minimum Order Quantity1 tons after confirmed the samples

-

Packaging DetailsEP paper + Kraft Paper + Plywood pallet, as per export packing standard, custom packing is available

-

Delivery Timewithin 16 days after received your deposits

-

Payment Terms50% should be paid before produce, the balance should be paid before shipment.

-

Supply Ability6500Tons/Month

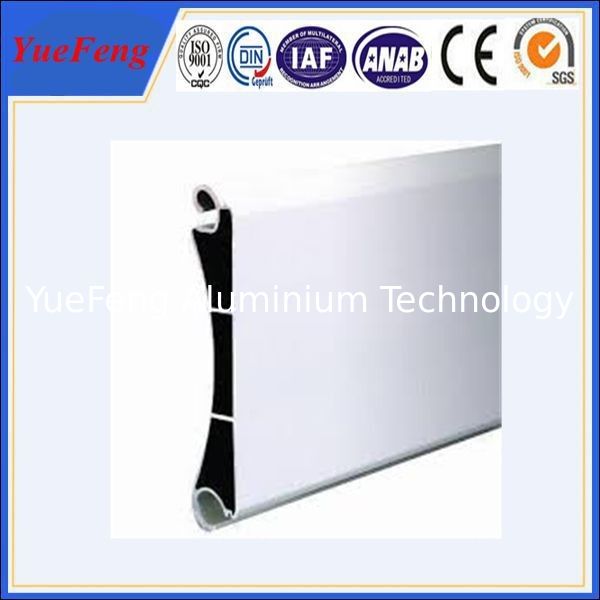

Aluminium profiles for roller shutter door Manufacturer

| 1. Material | Aluminium alloy; 6063, 6061, 6082, 6005, T5, T6, |

| 2. Section Shapes | I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot and other complicated shapes by custom design. |

| 3. Surface treating | Mill/Anodized(oxidation)/Sand blast/Powder coating/Electrophoresis/Wood grain… |

| 4. Application | 1) - for Window and door frames |

| 3) - for Building curtain glass walls | |

| 4) - for Solar panel frames, Solar mounting / roofing brackets | |

| 5) - for Industry assembly lines equipment. | |

| 6) - for Heatsinks | |

| 7) - for LED lighting | |

| 8)- other by custom design size and dimension | |

| 5. Production lines | 1) 5 melting and casting production lines |

| 2) 25 extruding production lines(from 500tons to 3000tons and meet different customer's demands) | |

| 3) 6 anodizing and electrophresis production lines | |

| 4) 2 powder coating production lines | |

| 5) 4 wooden grain production lines | |

| 6) 2 heat insulation broken bridge production lines | |

| 7) 2 wiredrawing and polishing production lines | |

| 6. Characteristic Services | 1). OEM Service. |

| 2). Design according to the customers' requirements. | |

| 3). more years' professional experience in research, manufacturing | |

| 4). Our modern deep processing center can provide machining such as Cutting, punching, drilling, etc. | |

| 7. Quality Control | We operate the most strict quality control system, the detection is from the material, production process, |

| to final product, and ensure the product quality and traceability. | |

| 8.Process | Die design→Die making→Smelting&alloying→QC→Extruding→Cutting→Heat Treatment→ |

| QC→Surface treatment→QC→Welding→Packing→QC→Shipping→After Sale Service | |

| 9.Standard | GB5237-2008 equal to EN12020-1.2(2001) |

| 10.Payment | T/T: 30% for deposit, the balance will be paid before delivery |

| 11.Packaging Detail: | Inside : packed with plastic film to protect each piece |

| Outside: Wrap to be bundles by waterproof craft paper or EPE film. Customized request available | |

| 12.Lead Time | Die Developing and Sample testing: 5-7 days . |

| Mass Production: 10-15days. |

![]()

![]()

|

Alloy: |

6063 |

6061 |

6060 |

6005 |

6082 |

6463 |

7075 |

|

Temper : |

T5 |

T6 |

T4 |

|

|

|

|

|

Standard: |

DIN |

AAMA |

AS |

CHINAGB |

|

|

|

|

Certification: |

ISO9001: 2008. |

||||||

|

Surface Finish: |

Mill finish |

Anodizing |

Powder Coating |

Wood Grain |

Electrophoresis |

Polished |

Brushed |

|

Color: |

Anodizing: |

Silver, bronze, champagne, titanium, nickel, golden yellow, etc. |

|||||

|

Anodizing thickness is up to 25um. |

|||||||

|

Powder Coating: |

White, black, bronze, grey, green, etc . |

||||||

|

Powder coating thickness is more than 60um. |

|||||||

|

Wood Grain: |

1. Italian MENPHIS transfer printing paper. |

||||||

|

2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. |

|||||||

|

3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah, Snow gum, etc. |

|||||||

|

Electrophoresis: |

Silver, nickel, golden yellow, black, champagne, etc |

||||||

|

Polishing |

Silver, nickel, golden yellow, black, etc |

||||||

|

Brushing: |

Silver, nickel, golden yellow, black, bronze, etc |

||||||

|

Machining: |

Cutting, punching, drilling, bending, weld, mill, CNC, etc. |

||||||

|

OEM customized aluminium extrusion profiles are available. |

|||||||

|

Alloy |

Chemical Composition |

||||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others |

Al(Min) |

||

|

6061 |

Al Mg 1 SiCu |

0.4- 0.8 |

0.7 |

0.15- 0.4 |

0.15 |

0.8- 1.2 |

0.04- 0.35 |

0.25 |

0.15 |

0.15 |

Remainder |

|

6063 |

Al Mg Si |

0.2- 0.6 |

0.35 |

0.1 |

0.1 |

0.45- 0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Remainder |

More information or products please contact us or enter our Website: http://www.profiles-aluminum.com; or http://aluminum-extrusion.sell.everychina.com/.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

More information or products please contact us or enter our Website: http://www.profiles-aluminum.com; or http://aluminum-extrusion.sell.everychina.com/.