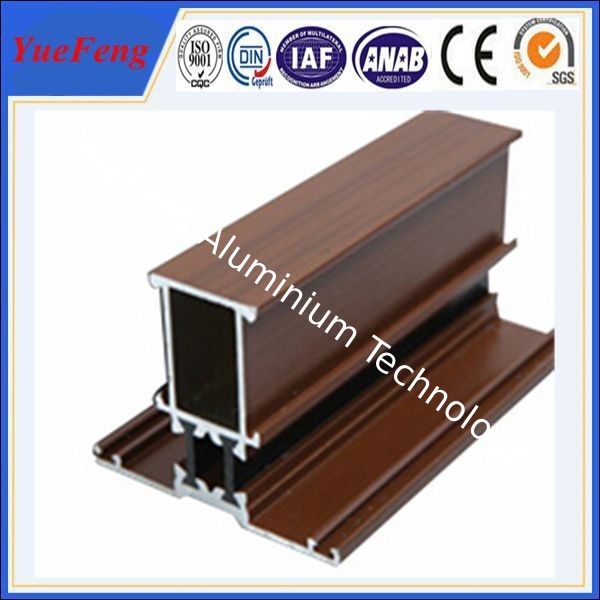

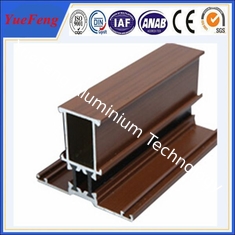

Import China Products Aluminium Profile Doors And Windows Wooden Grain Aluminium Windows

-

ColourSilvery, Black, Any Color Is Available As Per Require

-

Surface TreatmentAnodized, Powder Coating, Electrophoresis, Wooden-pattern Transfer...

-

LifetimeMore Than 10 Years

-

MOQ1Tons

-

Company HonorChina Famous Trademark

-

SkypeJames.wang0307

-

WeChatJameswang0307

-

WhatsApp/Viber/Mobile0086 18662963676

-

QQ1021035269

-

Production Capability6500 Tons/month

-

OEM/ODMAvailable

-

CO,FormA, FormB, FormE...Available

-

SamplesFree

-

Web1Http://www.profiles-aluminum.com

-

Web2Http://aluminum-extrusion.sell.everychina.com/

-

E-mail01Jameswang0307@gmail.com

-

E-mail03Sales@profiles-aluminum.com

-

MaterialsAA6063,6061,6060....T5/T6...

-

Place of OriginJiangyin, Jiangsu, China

-

Brand NameYueFeng

-

CertificationISO9001

-

Model NumberYF-276

-

Minimum Order Quantity1 tons after confirmed the samples

-

Packaging DetailsEP paper + Kraft Paper + Plywood pallet, as per export packing standard, custom packing is available

-

Delivery Timewithin 16 days after received your deposits

-

Payment Terms50% should be paid before produce, the balance should be paid before shipment.

-

Supply Ability6500Tons/Month

Import China Products Aluminium Profile Doors And Windows Wooden Grain Aluminium Windows

Aluminum windows and doors Profiles

1.High hardness, hard aluminum series.

2.Fair corrosion resistance. Heat treatable

3.Good workability and Good appearance

4.High quality and reasonable price.

5.china's leading manufacturer with more than 10 years experienced

YueFeng Technology is China's leading manufacturer of aluminum extrusion, aluminium profiles, aluminum windows&doors profiles, industry profiles, heat sinks, solar frame, solar mounting, aluminum tubes, LED profiles, Electric shell profiles, shutter doors profiles, all kinds of custom aluminum extrusion as per customer's drawings or samples.

| 1. Material | Aluminium alloy; 6063, 6061, 6082, 6005, T5, T6, |

| 2. Section Shapes | I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot and other complicated shapes by custom design. |

| 3. Surface treating | Mill/Anodized(oxidation)/Sand blast/Powder coating/Electrophoresis/Wood grain… |

| 4. Application | 1) - for Window and door frames |

| 3) - for Building curtain glass walls | |

| 4) - for Solar panel frames, Solar mounting / roofing brackets | |

| 5) - for Industry assembly lines equipment. | |

| 6) - for Heatsinks | |

| 7) - for LED lighting | |

| 8)- other by custom design size and dimension | |

| 5. Production lines | 1) 5 melting and casting production lines |

| 2) 25 extruding production lines(from 500tons to 3000tons and meet different customer's demands) | |

| 3) 6 anodizing and electrophresis production lines | |

| 4) 2 powder coating production lines | |

| 5) 4 wooden grain production lines | |

| 6) 2 heat insulation broken bridge production lines | |

| 7) 2 wiredrawing and polishing production lines | |

| 6. Characteristic Services | 1). OEM Service. |

| 2). Design according to the customers' requirements. | |

| 3). more years' professional experience in research, manufacturing | |

| 4). Our modern deep processing center can provide machining such as Cutting, punching, drilling, etc. | |

| 7. Quality Control | We operate the most strict quality control system, the detection is from the material, production process, |

| to final product, and ensure the product quality and traceability. | |

| 8.Process | Die design→Die making→Smelting&alloying→QC→Extruding→Cutting→Heat Treatment→ |

| QC→Surface treatment→QC→Welding→Packing→QC→Shipping→After Sale Service | |

| 9.Standard | GB5237-2008 equal to EN12020-1.2(2001) |

| 10.Payment | T/T: 50% for deposit, the balance will be paid before shipment |

| 11.Packaging Detail: | Inside : packed with plastic film to protect each piece |

| Outside: Wrap to be bundles by waterproof craft paper or EPE film. Customized request available | |

| 12.Lead Time | Die Developing and Sample testing: 5-7 days . |

|

Mass Production: 10-15days. More information or products please contact us or enter our Website: http://www.profiles-aluminum.com; or http://aluminum-extrusion.sell.everychina.com/. |

![]()

![]()

|

Alloy: |

6063 |

6061 |

6060 |

6005 |

6082 |

6463 |

7075 |

|

Temper : |

T5 |

T6 |

T4 |

|

|

|

|

|

Standard: |

DIN |

AAMA |

AS |

CHINAGB |

|

|

|

|

Certification: |

ISO9001: 2008. |

||||||

|

Surface Finish: |

Mill finish |

Anodizing |

Powder Coating |

Wood Grain |

Electrophoresis |

Polished |

Brushed |

|

Color: |

Anodizing: |

Silver, bronze, champagne, titanium, nickel, golden yellow, etc. |

|||||

|

Anodizing thickness is up to 25um. |

|||||||

|

Powder Coating: |

White, black, bronze, grey, green, etc . |

||||||

|

Powder coating thickness is more than 60um. |

|||||||

|

Wood Grain: |

1. Italian MENPHIS transfer printing paper. |

||||||

|

2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. |

|||||||

|

3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah, Snow gum, etc. |

|||||||

|

Electrophoresis: |

Silver, nickel, golden yellow, black, champagne, etc |

||||||

|

Polishing |

Silver, nickel, golden yellow, black, etc |

||||||

|

Brushing: |

Silver, nickel, golden yellow, black, bronze, etc |

||||||

|

Machining: |

Cutting, punching, drilling, bending, weld, mill, CNC, etc. |

||||||

|

OEM customized aluminium extrusion profiles are available. |

|||||||

|

Alloy |

Chemical Composition |

||||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others |

Al(Min) |

||

|

6061 |

Al Mg 1 SiCu |

0.4- 0.8 |

0.7 |

0.15- 0.4 |

0.15 |

0.8- 1.2 |

0.04- 0.35 |

0.25 |

0.15 |

0.15 |

Remainder |

|

6063 |

Al Mg Si |

0.2- 0.6 |

0.35 |

0.1 |

0.1 |

0.45- 0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

Remainder |

More information or products please contact us or enter our Website: http://www.profiles-aluminum.com; or http://aluminum-extrusion.sell.everychina.com/.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

More information or products please contact us or enter our Website: http://www.profiles-aluminum.com; or http://aluminum-extrusion.sell.everychina.com/.