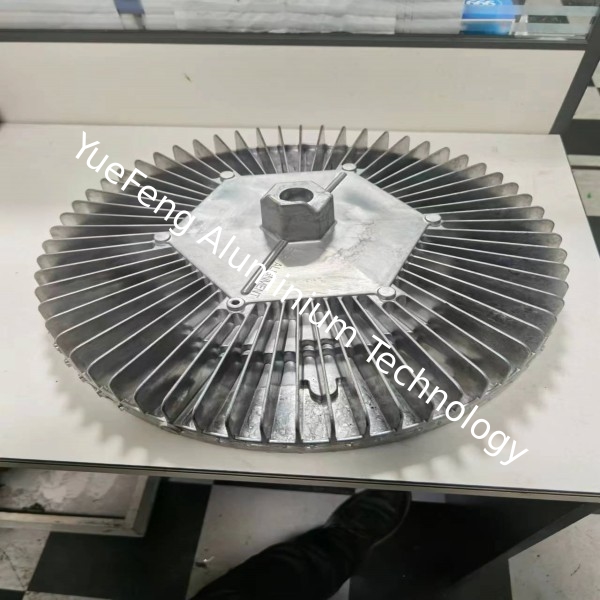

Oem Die Casting Aluminium Parts, China Die Casting Aluminum Manufacturers

-

ColourSilvery, White, Black, Any Color Is Available As Per Require

-

Surface TreatmentAnodized, Powder Coating,

-

LifetimeMore Than 10 Years

-

MOQ1Tons

-

Company HonorChina Famous Trademark

-

SkypeJames.wang0307

-

WeChatJameswang0307

-

WhatsApp/Viber/Mobile0086 18662963676

-

Production Capability6500 Tons/month

-

OEM/ODMAvailable

-

CO,FormA, FormB, FormE...Available

-

SamplesFree

-

E-mail03Sales@profiles-aluminum.com

-

MaterialsADC12....

-

Place of OriginJiangyin, Jiangsu, China

-

Brand NameYueFeng

-

CertificationISO9001, SGS...

-

Model NumberYF-844

-

Minimum Order Quantity1 tons after confirmed the samples

-

PriceNegotiation

-

Packaging DetailsEP paper + Kraft Paper + Plywood pallet, as per export packing standard, custom packing is available

-

Delivery Timewithin 12 days after received your deposits

-

Payment Terms50% should be paid before produce, the balance should be paid before shipment.

-

Supply Ability6500Tons/Month

Oem Die Casting Aluminium Parts, China Die Casting Aluminum Manufacturers

Advantages, disadvantages and Application of Die casting Aluminum Alloy.

First, advantages:

1. Aluminum alloy has good thermal conductivity, electrical conductivity and cutting performance.

2. Aluminum alloy has good filling performance because of its small linear shrinkage.

3. Aluminum alloy has low density and high strength, and the ratio of tensile strength to density is 9: 15. It also maintains good mechanical properties when working at high or low temperature.

4.

Aluminum alloy has good corrosion resistance and oxidation resistance. Most aluminum alloys have good corrosion resistance in fresh water, seawater, concentrated nitric acid, nitric acid, gasoline and various organic compounds.

Second, shortcomings:

1. Low hardness and poor wear resistance at the same time.

2. During solidification, the volume shrinkage is relatively large, about 6.6%.

3. The linear expansion coefficient is relatively high.

4. Easy to stick mold, so you need to strictly control the iron content in the range of 0.8% Mel 0.9%.

5. The melting point is low and the use of high temperature is limited.

Second, application:

Aluminum alloy can replace bronze as low-speed, medium-temperature and heavy-duty bearings, and the price is 50% lower than that of bronze bearings.

Profiles can also be produced by continuous casting or centrifugal casting to manufacture bushings and bushings.

It can also be used to make moulds, widely used in making bearings, various pipe joints, pulleys and all kinds of castings subjected to impact and wear.

Yuefeng die casting aluminum alloy is widely used in automobile, engineering construction, electric power, electronics, computer, household appliances, high fidelity speakers, military ships, aviation, aerospace and other military fields.